Seaport Shipping & Trading

This solution in a nutshell:

- Mobile, discontinuous totalising weigher for unloading ships

- Capacity of 500 m3/ hour

- Dust-free performance

- Stand-alone solution, including extractor

Why the customer chose Robbe Industries …

- Automation

- Tailor-made flexibility

- Flowing products: grains, salts, premixes, …

Customer data

Company

Seaport Shipping & Trading Zeebrugge

Website

www.seaportshipping.be

Mobile discontinuous totalising hopper scale

As a company specialized in storage and transhipment, Seaport Shipping needs reliable and accurate measuring equipment. In order to load and unload ships in a quick and efficient way on the entire terrain, an automatic mobile discontinuous totalising hopper scale is the perfect solution. Moreover, this hopper scale can move a huge tonnage.

The existing ship unloader of Seaport Shipping, who had already been converted by Robbe Industries before, finally had to be replaced. Moreover, the company asked us to find a solution to unload quicker and in a more efficient and dust-free way.

That is why Robbe Industries designed, built and installed a custom machine for Seaport Shipping.

Objectives for new weigher

- Solve dust problems with old weigher

- Complete stand-alone system with compressor and extractor

- Preparing the machine in a quick, secure way and starting up on different locations

- Limited height available

Solution

The engineers of Robbe Industries have switched each single problem of this custom-built machine into concrete solutions. First, they developed the complete hopper scale in 3D. Hence, they could be sure that all external purchased parts would fit without any problem. We discussed all the plans with our customer. After their approval, we started with the production of the discontinuous totalising hopper scale.

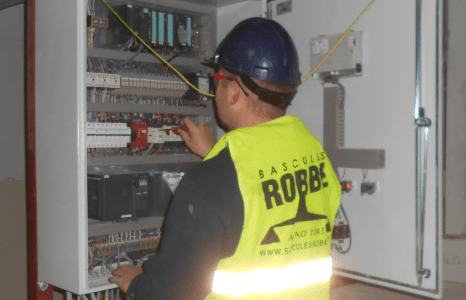

The clear and well-organized HMI control ensures a smooth start-up and secure performance of the machine. The HMI was installed at the side of the machine, together with the printer. The main control cabinets provided with Siemens PLC and a compressor of Atlas Copco were installed in the heated cabinet on the front of the device. They have an easy access, so they can easily be maintained and controlled.

During the start-up, also the hydraulic controlled outriggers are used. Subsequently, the machine levels itself, so one can always work in a secure way. Thus, the weigher performs in ideal circumstances.

The hopper scale has a flow rate of approximately 500 m3/hour, with which the filling capacities of the different raw materials are stocked in the Siemens PLC controller. Hence, the user only has to select the right product and the Siwarex module takes care of the next weighing steps.

Via a GPRS module, all unloading data are available for further development in the ERP system.

In order to prevent dust formation, several measures were taken. Therefore, the hopper was specially designed and all transitions were closed. By means of additional screens, the operator can choose which side of the hopper he will close to protect against the wind. Finally, a complete dust extractor with automatic cleaning filters was provided. By means of this extractor, also the dust of the outflow is extracted.

First, the machine was completely rebuilt by Robbe Industries and was transported via special transport to Zeebrugge. There, a whole team of installers took care of a smooth construction and operation of the machine. After the calibration according to the standards of OIML R107 for discontinuous totalising weighers, the machine is ready to use for the customer. The GPRS module ensures that a technician can follow everything closely at a distance. Moreover, he can answer any question and solve any solution of the customer live.

Also, for the maintenance and the calibration of the discontinuous totalising weigher, Seaport Shipping can count on the experienced team of Robbe Industries.

Can we help you?

Describe your project and needs by filling in the form below. We will answer you within two working days and explain how we can help you.

View more realisations

Flow-through roadways replace Aveve

112 existing tipping weighers replaced leads to doubling of existing capacity

Can we help you?

Describe your project and needs by filling in the form below. We will answer you within two working days and explain how we can help you.